Amasondo ayisikiwe ayizesekeli zamathuluzi abalulekile ezimbonini eziningi, kusukela kwezokusebenza ngensimbi kuya kwezokwakha. Lezi zinsiza zamathuluzi zidinga ukuba ziqine, ziqine futhi ziphephe ukuzisebenzisa. Yingakho amazinga okuphepha nokuhlolwa kufanele kulandelwe ukuze kuqinisekiswe ikhwalithi yamasondo ayisikiwe.

Enye yezindinganiso ezijwayelekile zamazwe omhlaba zokuhlola amadiski asikiwe yi-EN 12413. Leli zinga lihlanganisa izidingo zokuphepha zamasondo anqanyuliwe. Njengengxenye yenqubo yokuthobela imithetho, amadiski okusika kufanele enze inqubo yokuhlola eyaziwa ngokuthi ukuhlolwa kwe-MPA.

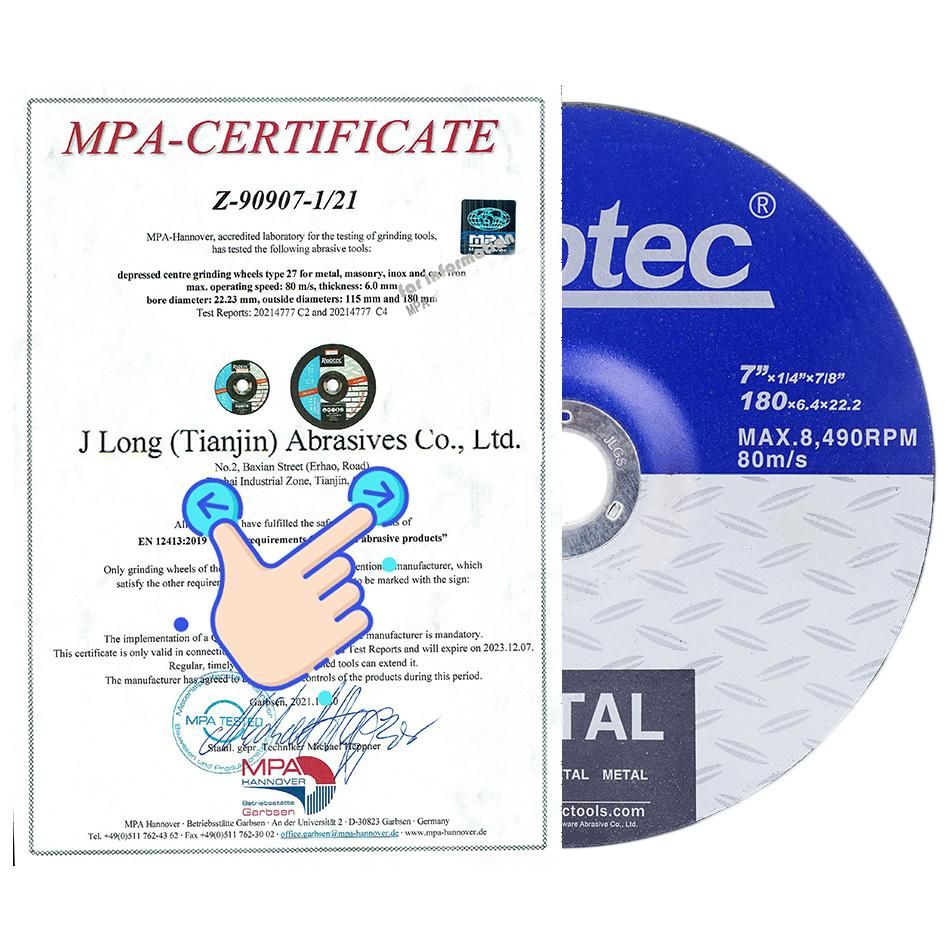

Ukuhlolwa kwe-MPA kuyithuluzi lokuqinisekisa ikhwalithi eliqinisekisa ukuthi amasondo anqanyuliwe athobela izinga le-EN12413. Ukuhlolwa kwe-MPA kwenziwa amalabhorethri azimele agunyazwe ukuthi enze ukuhlola kokuphepha kumadiski asikiwe. Ukuhlolwa kuhlanganisa zonke izici zekhwalithi yediski, okuhlanganisa amandla aqinile, ukwakheka kwamakhemikhali, ukuqina kobukhulu, ukumelana nomthelela nokunye.

Ukuze ama-cut-off disc aphumelele ukuhlolwa kwe-MPA, kufanele ahlangabezane nazo zonke izimfuneko zokuphepha futhi aphumelele ukuhlola okuqinile kokulawula ikhwalithi. Ukuhlolwa kwe-MPA kuyindlela ethembekile yokuqinisekisa ukuthi isondo elisikiwe liphephile ukuthi lingasetshenziswa futhi lihlangabezana nazo zonke izidingo zokuphepha.

Uma ungumsebenzisi wesondo elisikiwe, kufanele ubheke imikhiqizo ephumelela ukuhlolwa kwe-MPA. Lesi isiqinisekiso sakho sokuthi amadiski owasebenzisayo ayikhwalithi ephezulu, aphephile futhi ahambisana nezindinganiso zokuphepha zamazwe ngamazwe.

Ngaphezu kokuhlolwa kwe-MPA, akhona amanye amathuluzi okuqinisekisa ikhwalithi angasetshenziswa ukuqinisekisa ukuphepha kwamasondo anqanyuliwe. Isibonelo, umkhiqizi angase enze ukuhlolwa kwangaphakathi kwamasondo anqanyuliwe ukuze aqinisekise ukuthi imikhiqizo yakhe ithobela izidingo ze-EN12413.

Ezinye izici zokusika amadiski adinga ukuhlolwa nokuqapha ukuze kuqinisekiswe ukuphepha kwawo zifaka:

1. Usayizi nokuma: Ububanzi nobukhulu bediski yokusika kufanele bufanele okokusebenza okuhlosiwe.

2. Isivinini: Idiski yokusika akumele yeqe isivinini esilinganiselwe esiphezulu sempahla.

3. Amandla okubopha: Isibopho phakathi kwezinhlamvu ezihuquzelayo kanye nediski kufanele kuqine ngokwanele ukuvimbela ukulimala kwempahla futhi kuvimbele idiski ukuba indize ngesikhathi sokusetshenziswa.

4. Amandla okuqina: i-disc yokusika kufanele ikwazi ukumelana namandla akhiqizwa ngesikhathi sokusetshenziswa.

5. Ukubunjwa Kwekhemikhali: Impahla esetshenziselwa ukwakha isondo elisikiwe kufanele ingabi nakungcola okungenza buthaka isondo elisikiwe.

Sengiphetha, ukuphepha kuyinto ehamba phambili ekwenziweni nasekusetshenzisweni kwamasondo ayisikiwe. Ukuhlolwa kwe-MPA kuyithuluzi elibalulekile lokuqinisekisa ukuthi amadiski asikiwe ahambisana nezinga le-EN12413. Ngaphambi kokuthenga amasondo asikiwe, qiniseka ukuthi ahlolwe yi-MPA ukuze kuqinisekiswe ukuphepha kwawo kanye nekhwalithi.

Isikhathi sokuthumela: 18-05-2023